New wastewater treatment facility uses green technology

The District of Sechelt's new Water Resource Centre won an FCM Sustainable Communities Award for its community-friendly facility that uses an innovative, odour-free method to turn wastewater into high-quality reclaimed water and Class A compost.

Read the case study below to learn about the project highlights, its challenges and the lessons learned that can help your community in planning similar projects.

About the project

| Municipal population | Project duration | Total project value |

|---|---|---|

| 9,500 | January 2012–December 2015 | $25 million |

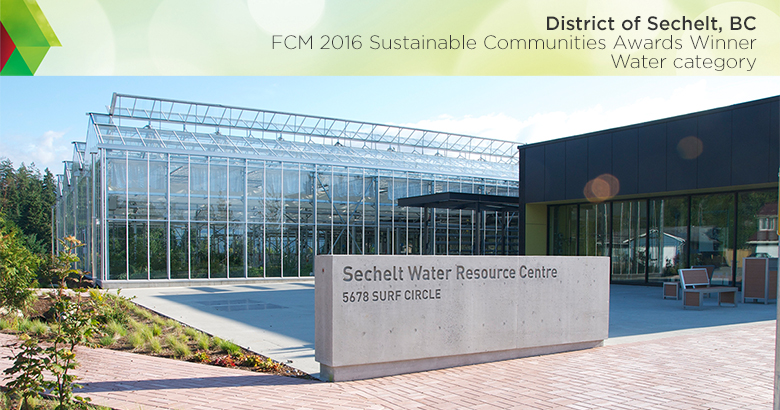

Located in the middle of town between residential housing and the Sechelt Marsh nature reserve, the new Sechelt Water Resource Centre exceeds the treatment capacity of the two older wastewater treatment plants it replaces. The treated effluent is so clean that it eliminates the need to extend an outfall pipe into the Pacific Ocean.

The facility is designed to meet LEED® Gold certification and includes:

- a 12-kilowatt solar energy roof

- a heat recovery system

- comprehensive odour-control technology

- tertiary treatment using ultrafiltration membranes and UV rays

It is the first in North America to use a sequencing batch reactor process in which plants are suspended over treatment tanks enclosed in a greenhouse. The plant roots enhance the biological treatment process by making it more efficient, reducing energy and space requirements, and controlling odour. The landscaped grounds are fully accessible to the public and include habitat restoration of a small stream area. The centre, built with support from FCM's Green Municipal Fund, also hosts educational tours.

"The water resource facility gives Sechelt a clear vision for the future. It allows us to take a waste product and turn it into a resource."

— Mayor Bruce Milne, District of Sechelt

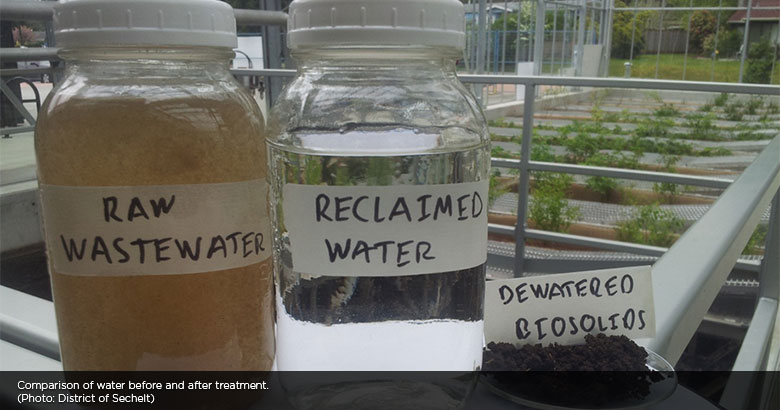

Secondary effluent is filtered through ultrafiltration membranes and disinfected with ultraviolet light. The resulting water surpasses standards for indirect potable uses such as irrigation. A local company composts the biosolids into a Class A compost product suitable for unrestricted use.

Project Highlights

Results

| Environmental | Economic | Social |

|---|---|---|

|

|

|

Challenges

- Although the district consulted with the public prior to launching the project, community members voiced concerns prior to and during construction. Ongoing public engagement throughout the process would have helped to address concerns.

- Working with innovative technology meant that the district had to educate people about the technology without any North American examples to demonstrate its success.

Lessons learned

- Consider a design-build approach, which greatly simplifies project delivery and ensures greater accountability within the project team.

- Hire an experienced project manager and a separate owner's engineer, to oversee the logistic and technical aspects of the project, respectively.

- Secure a strong commitment from elected officials and municipal staff to stay open to innovation and creative solutions, even if this means entering "uncharted territory."

- Make community engagement a priority and share all information as soon as it is available. Work with the community to establish the vision and objectives, while consulting specialists on the technical aspects.

More information

Connie Jordison, Communications Manager

District of Sechelt, British Columbia

T. 604-885-1986

Want to explore all GMF-funded projects? Check out the Projects Database for a complete overview of funded projects and get inspired by municipalities of all sizes, across Canada.